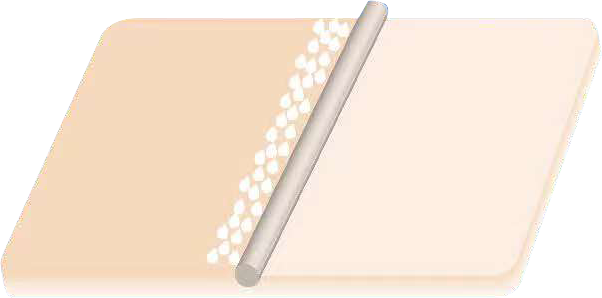

| Process: | The PU Monomer is forming into foam to be an absorbent layer for silicone foam dressing |

| Material: | PU Monomer |

| Features: |

|

| Process Diagram: |

|

| Picture: |

|

| Advantage: |

The main exudate absorbent layer of silicone foam, dressing With absorption and retain, At the same time, it has the effect of buffering external impact |

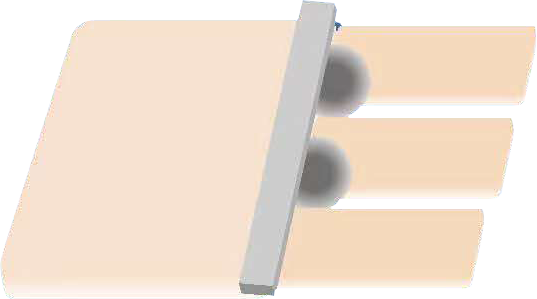

| Process: | Top Layer Making, TPU film Coating |

| Material: |

|

| Features: |

|

| Process Diagram: |

|

| Picture: |

|

| Advantage: |

|

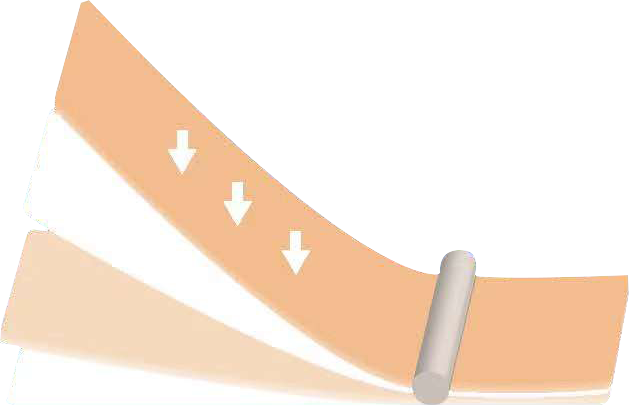

| Process: | According to the physical characteristics of the semi-finished substrate, the pneumatically controlled rolling blade slitting machine is selected for slitting of the substrate . In order to reduce the multi-layer structural damage of the cutting surface caused by friction between the material and the knife, we added tensile adjustment to control the material. |

| Material: | Laminated substrate |

| Features: | Tolerance: ±0.2mm |

| Process Diagram: |

|

| Picture: |

|

| Advantage: |

|

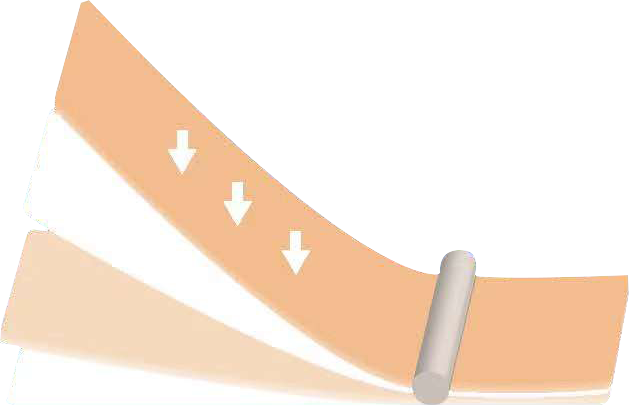

| Process: | Laminating different layer to one piece |

| Material: | TPU Film, Super Absorption Layer ,Foam, Wound Contact Layer |

| Features: | Smooth Appearance without wrinkle |

| Process Diagram: |

|

| Picture: |

|

| Advantage: |

|

| Process: | Forming the foam dressing final size. |

| Material: | TPU Film, Super Absorption Layer ,Foam, Wound Contact Layerss |

| Features: |

Smooth Appearance without wrinkle Size control ±0.2mm |

| Process Diagram: |

|

| Picture: |

|

| Advantage: |

Low trauma upon removal Conformable and flexible Secure fixation Repositionable Little-to-no residue upon removal Suitable for sensitive skin Breathable (when perforated) |